Lotus Pink Glass | Black Label | Large Mousepad

Micron-level etching process

4mm thickness of BQ grade aluminum silicon glass material

Fully tempered with a hardness of Mohs 7h

CNC cutting and polishing

Composite coating curing technology

Full coverage PU bottom adhesive

Do not use alcohol wipes to clean

Do not use glass feet or other hard adhesive on the glass mouse pad

Etching Process

The surface adopts a micron-level etching process, with uniform and delicate textures, with Mobile Sampling Imaging Optimization with most mice on the market to help optimize tracking.

The product is divided into a fine surface and a coarse surface. The fine surface is suitable for long TTK shooting games and MOBA games, while the coarse surface increases control, meeting the quick stopping and positioning needs of short TTK games users.

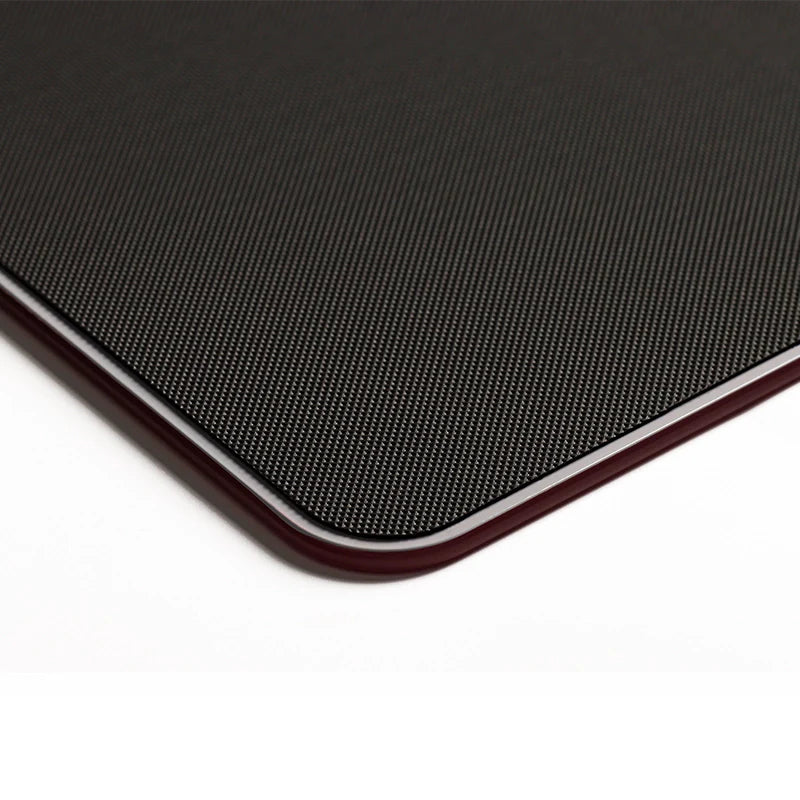

In order to present exquisite craftsmanship in every piece, we have performed overall CNC cutting and polishing on the product. The curved edges effectively reduce wrist discomfort. The high-gloss treatment gives the product a smooth edge like a jade.

Full coverage PU anti-slip

For the bottom anti-slip layer, we use a safe full coverage PU material, which ensures a flat and stable surface on the desk, suitable for various intense scenarios.

Composite coating curing technology

To reduce the occurrence of the glass pad sticking to the skin or collecting dust, we have used composite coating curing technology on the product surface, which maintains a smooth touch and reduces any roughness over time.

Product Story

After a year of repeated overturning and remaking, in June of this year, EspTiger’s first glass mouse pad "Lotus" will be introduced to everyone.

For safety and flatness, we have chosen a 4mm thickness of BQ grade aluminum silicon glass material and performed overall tempering, resulting in a hardness of Mohs 7h. This not only enhances durability but also ensures safety and flatness.

4mm thickness of BQ grade aluminum silicon glass material

Fully tempered with a hardness of Mohs 7h

CNC cutting and polishing

Composite coating curing technology

Full coverage PU bottom adhesive

Do not use alcohol wipes to clean

Do not use glass feet or other hard adhesive on the glass mouse pad

Etching Process

The surface adopts a micron-level etching process, with uniform and delicate textures, with Mobile Sampling Imaging Optimization with most mice on the market to help optimize tracking.

The product is divided into a fine surface and a coarse surface. The fine surface is suitable for long TTK shooting games and MOBA games, while the coarse surface increases control, meeting the quick stopping and positioning needs of short TTK games users.

In order to present exquisite craftsmanship in every piece, we have performed overall CNC cutting and polishing on the product. The curved edges effectively reduce wrist discomfort. The high-gloss treatment gives the product a smooth edge like a jade.

Full coverage PU anti-slip

For the bottom anti-slip layer, we use a safe full coverage PU material, which ensures a flat and stable surface on the desk, suitable for various intense scenarios.

Composite coating curing technology

To reduce the occurrence of the glass pad sticking to the skin or collecting dust, we have used composite coating curing technology on the product surface, which maintains a smooth touch and reduces any roughness over time.

Product Story

After a year of repeated overturning and remaking, in June of this year, EspTiger’s first glass mouse pad "Lotus" will be introduced to everyone.

For safety and flatness, we have chosen a 4mm thickness of BQ grade aluminum silicon glass material and performed overall tempering, resulting in a hardness of Mohs 7h. This not only enhances durability but also ensures safety and flatness.